Manufacturers worldwide are rapidly embracing advanced simulation and data technologies to streamline operations, cut costs, and boost product quality. Among the most transformative of these innovations is the concept of digital replicas of physical assets and processes that enable real-time monitoring, testing, and optimization across an entire production ecosystem. As more plants become hyperconnected and data-driven, these virtual models are shifting from experimental pilots to core components of modern industrial strategies.

In this landscape, manufacturers are rethinking how they design equipment, manage facilities, and maintain global supply chains. The convergence of IoT sensors, cloud computing, AI, and robust analytics platforms is making it possible to create accurate and dynamic representations of machines, production lines, and even full factories. These virtual counterparts are not static CAD models; they are living systems that continuously evolve based on incoming data, enabling a new level of foresight, agility, and collaboration throughout the value chain.

As adoption accelerates, global manufacturers face a critical challenge: coordinating complex technical information across borders, languages, and regulatory regimes. Engineering documentation, compliance reports, safety guidelines, and maintenance manuals must be accurately localized for teams and authorities worldwide. This is where certified translation services become essential for ensuring that highly technical documentation remains precise, compliant, and legally recognized in every target market, supporting smooth deployment and operation of advanced digital manufacturing solutions.

1. Redefining Product Design and Development

One of the most impactful uses of advanced virtual manufacturing models is in product design and development. Engineers can virtually prototype complex components, run extensive simulations, and test design alternatives before committing to physical production. This approach dramatically reduces the number of physical prototypes needed, cutting both time to market and development costs. It also supports greater innovation, as teams can explore more design variations without incurring prohibitive expenses.

Furthermore, these models enable concurrent engineering: mechanical, electrical, and software teams work on a shared virtual representation of a product, identifying conflicts early. For example, thermal behavior, structural integrity, or electromagnetic interference can be assessed digitally at an early stage, minimizing redesigns and late-stage errors that traditionally cause delays and budget overruns.

2. Optimizing Production Lines Before Physical Deployment

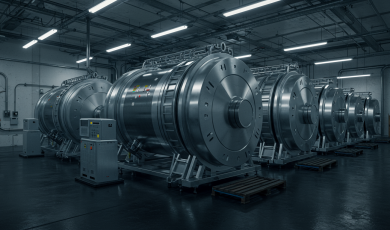

Advanced digital replicas of production lines allow manufacturers to virtually commission new equipment and processes. Virtual commissioning means that control logic, PLC programming, and line balancing scenarios are tested against a detailed digital model before the actual line is built or reconfigured. This significantly reduces ramp-up times and mitigates the risk of bottlenecks or unexpected interactions between machines once the line is live.

By simulating different production scenarios, manufacturers can understand the impact of layout changes, new product introductions, or throughput increases. They can identify the optimal configuration of conveyors, robots, workstations, and storage areas to achieve target performance. When the final physical line is activated, it already reflects lessons learned from the virtual environment, enhancing confidence in meeting volume and quality targets.

3. Enabling Predictive Maintenance and Reduced Downtime

Predictive maintenance is one of the strongest value propositions driving adoption of data-rich virtual models. By continuously feeding sensor data from equipment into its corresponding virtual counterpart, manufacturers can monitor asset health in real time. Advanced analytics can detect deviations from normal behavior and predict failures before they occur, allowing maintenance teams to schedule interventions at optimal moments.

This approach reduces unplanned downtime, a major source of lost revenue in manufacturing. It also extends the life of critical machinery, as interventions are based on actual condition rather than generic time-based schedules. Maintenance teams become more strategic, focusing on early warnings and root-cause analysis derived from the virtual model, instead of reacting to breakdowns after they disrupt production.

4. Improving Quality Control and Process Consistency

Virtual manufacturing environments, updated with production data, can be powerful tools for quality control. By analyzing variations in process parameters and outcomes over time, quality engineers can identify patterns that lead to defects or rework. The virtual model makes it easier to understand how minor changes in temperature, pressure, speed, or material properties propagate through the process and affect final product quality.

Once those relationships are understood, manufacturers can implement better process controls and automated adjustments that maintain optimal operating windows. Over the long term, this leads to increased yield, reduced scrap, and more consistent product performance. For regulated industries such as automotive, aerospace, and medical devices, the ability to trace quality issues back through a detailed digital history is also crucial for compliance and continuous improvement.

5. Enhancing Worker Training and Safety

Advanced virtual representations are also reshaping how employees are trained. New operators, maintenance staff, and engineers can learn on interactive simulations that accurately reproduce plant layouts, machine behavior, and process steps. This reduces the need to slow or interrupt production for training and lowers the risk of accidents associated with inexperienced staff working directly on live equipment.

Safety procedures and emergency responses can be practiced virtually, ensuring that teams are prepared for rare but critical events such as equipment failures, fires, or hazardous material leaks. Because the virtual environment matches the real plant in detail, lessons learned transfer directly to the physical workplace, supporting a safer and more competent workforce.

6. Driving Supply Chain Visibility and Collaboration

Beyond the factory floor, digital representations of products and production processes support better supply chain collaboration. Suppliers, logistics providers, and customers can interact with shared virtual models to plan capacity, design packaging, and coordinate delivery schedules. For example, a component supplier can validate that their parts integrate correctly with a customer’s assembly process by referencing the same virtual line.

This level of visibility helps reduce inventory buffers, shortens lead times, and improves responsiveness to demand fluctuations. It also encourages earlier collaboration during product development, as supply chain partners can provide input on manufacturability, packaging efficiency, and transportation constraints while designs are still flexible.

7. Supporting Regulatory Compliance and Documentation

Many industries face stringent regulatory requirements, from safety standards and environmental regulations to traceability and documentation obligations. Digital records generated by advanced manufacturing models can provide detailed audit trails for products and processes, documenting materials used, process parameters, and quality checks for every batch or serial number.

These records simplify compliance reporting, product certifications, and incident investigations. When regulators request evidence of how a product was manufactured or how a process ensures safety, manufacturers can reference time-stamped data and simulations rather than relying solely on manual logs or fragmented spreadsheets. This level of transparency builds trust with regulators and customers alike.

8. Scaling Global Operations and Localization

Multinational manufacturers often operate multiple plants producing similar products in different regions. Virtual models help ensure that best practices, process improvements, and engineering changes are consistently replicated across those sites. Once a new process has been validated virtually in one facility, it can be deployed more quickly and confidently in others, with adjustments made to reflect local conditions.

Localization does not end with process replication, however. Technical documentation, work instructions, safety signage, and compliance paperwork must be adapted for local languages and regulatory requirements. By pairing robust virtual models with accurate linguistic and regulatory localization, manufacturers can maintain consistency in performance and safety while respecting local norms and laws.

Preparing for a More Intelligent Manufacturing Future

The increasing adoption of advanced virtual counterparts in manufacturing reflects a broader shift toward data-driven, intelligent production systems. As these technologies move from niche experiments to mainstream tools, manufacturers that embrace them gain a powerful advantage in innovation speed, operational efficiency, product quality, and global coordination.

To fully realize these benefits, organizations must invest not only in technology, but also in the supporting ecosystem of skills, standards, and communication. From design and engineering to maintenance and compliance, accurate and accessible information is the foundation of success. Companies that combine sophisticated virtual models with reliable, globally consistent documentation and communication practices will be best positioned to compete in an increasingly connected manufacturing landscape.